scratch test nanoindentation|nano indentation depth testing : white label Principle and Methods of Nanoindentation Test. 2.1 Overview of Nanoindentation Technique. Indentation test is a simple and effective method in the assessment of mechanical properties . EST = Estorno. DEP = Depósito. CH = Cheque. Ao aparecer essa sigla no seu extrato bancário saiba que foi depositado um valor na sua conta através de cheque, mas este .

{plog:ftitle_list}

Resultado da 29 de jun. de 2023 · the-end-of-love Scanner Internet Archive HTML5 Uploader 1.7.0. plus-circle Add Review. comment. Reviews There are no reviews yet. Be the first one to write a review. 19 Views . DOWNLOAD OPTIONS download 1 file . H.264 IA download. download 1 file . ITEM .

We performed nanoindentation and scratch tests in a KLA (Agilent, Keysight) G200 Nanoindenter. The nanoindentation was executed in 5-test batches using a Berkovich tip with . Scratch test results for amorphous carbon films (a-C:H) containing silicon. The micrographs are for a 614 nm thick film (top) and a 366 nm thick film (bottom). Large .The scratch test is a simple and widely used method for investigating adhesion in thin films [6]. We defined scratch hardness as the load per unit load-bearing area during scratching, taking .

instron machine for tensile strength testing

Nanoindentation (NI) is a nano-mechanical test that provides the mechanical properties from precise compliance measurements. In addition, nanoindentation analysis is especially useful in measuring properties such as the modulus and .Principle and Methods of Nanoindentation Test. 2.1 Overview of Nanoindentation Technique. Indentation test is a simple and effective method in the assessment of mechanical properties .

The scratch-testing option has the capability of characterizing scratch hardness, mar resistance, coating adhesion, film delamination, failure modes, etc. The quantitative scratch results are provided by measuring nanometers while . Using samples fabricated by reactive sputtering, nanoindentation hardness depth profiles were correlated with practical scratch resistance using three different scratch and abrasion test methods, simulating real world .The Nano Indenter ® G200 system is an accurate, flexible, user-friendly instrument for nanoscale mechanical indentation testing. The G200 measures Young’s modulus and hardness, including measurement of deformation over .

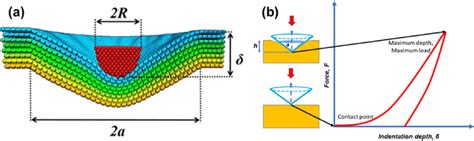

NANO Indenter © can also be used in scratch tests. By moving the sample stage, the indenter slides along the surface of the sample, and the tangential force is generated, . 2.2.1 Oliver and Pharr Method (O&P Method). O&P method is the most widely used model in nanoindentation technique. Typical indentation load–displacement curve and indentation profile before and after unloading process are shown in Figs. 2.1 and 2.2, respectively [].As the indenter is driven into the material, elastic deformation firstly occurs on the surface of .

Adhesion and hardness of galvanic layers by scratch test and nanoindentation Galvanic layers are crucial for protecting surfaces from corrosion and increasing durability. Accurate assessments using scratch tests and nanoindentation offer valuable insights into the adhesion and hardness of these coatings, helping in the enhancement of their . Nanoindentation test, which does not need a large sample volume, is a popular method to derive the fracture toughness of shale samples, especially for the shale samples that are not intact. 26, 27 The grid nanoindentation test has been applied in many shale formations including Bakken, 28, 29 Marcellus, 30 and Longmaxi Formation. 31 Currently, there are four . Nanoindentation has emerged as an important method for the evaluation of the mechanical response of small material volumes and thin films to applied loading. Here, we present a review of the measurement method, the instruments currently in use and the procedures for the analysis of the resulting data. . Scratch test results for amorphous .Request PDF | On Feb 1, 2023, Kouqi Liu and others published Comparison of shale fracture toughness obtained from scratch test and nanoindentation test | Find, read and cite all the research you .

In this paper we measured for the first time the scratch hardness of copper thin films and compared this with hardness measured from nanoindentation.Copper films with thicknesses in the range 100 nm to 500 nm were deposited by rf magnetron sputtering on silicon substrates. Scratch hardness was determined by CSM™ scratch tester using scratch widths . DOI: 10.1016/J.SURFCOAT.2006.10.031 Corpus ID: 56152998; Comparison between nanoindentation and scratch test hardness (scratch hardness) values of copper thin films on oxidised silicon substrates

Based on the statistical analysis of massive nanoindentation tests, the hydration products can be distinguished by Gaussian distribution of the frequency of indentation modulus and indentation hardness [138]. Berkovich probe is often used to measure the hydration products down to the scale of 250 nm in indentation tests. . With a scratch test .

Principle and Methods of Nanoindentation Test 2.1 Overview of Nanoindentation Technique Indentation test is a simple and effective method in the assessment of mechanical properties of materials and has widely been adopted in the latest century. Indentation technique evaluates the mechanical properties of materials by drivingnanoindentation and scratch test. So, novel nanoindentation and scratch test devices are required. And this is advanced technology and up to now there is no mature product for in situ .2.1 Nanoindentation Test Data The goal of the majority of nanoindentation tests is to extract elastic modulus . Fig. 2.3 Tip of a sphero-conical indenter used for nanoindentation and scratch testing. Nominal tip radius is 100 µm in this example. Tip radii of <1 µm are available (Courtesy CSIRO). 2. Nanoindentation Testing 23

Nanoindentation testing and scratch testing are methods to characterize material mechanical properties on micro to nano scales. Test methods include micro to nano-indentation testing for comparative and quantitative hardness and elastic modulus determination, stress and strain analysis, DMA and CSM testing and scratch testing for evaluation of wear resistance, . The scratch test is a convenient means of investigating material properties [1][2][3][4][5] such as scratch hardness, 6 coefficient of friction, 7,8 wear response, [9][10][11][12] fracture, 13 .Nanoindentation tester NHT³ measures the mechanical properties of coatings and bulk materials such as hardness, elastic modulus, and viscoelastic properties from the nano- to the microscale. . Adhesion and hardness of galvanic layers by scratch test and nanoindentation Application Reports.

A kind of experimental platform for in-situ nanoindentation and scratch test has been developed, which has high resolution of displacement and can be used to carry out nanoindentation and scratch .The objective of this study is to compare fracture toughness values obtained by two less conventional methods: nanoindentation test and scratch test, which could facilitate the evaluation of this important parameter on smaller samples and at different scales. A set of 5 Antrim shale samples characterized by different mineral compositions is . The scratch test starts by the tip reaching the surface and performing the thermal drift measurement, similarly to nanoindentation. This segment is followed by the pre-scan with a minor normal force of 0.15 mN to analyze the initial surface topography in the scratch track.

The values were E = 200 GPa; dc= 3 m; t =1 m which gave a work of adhesion of 19.6 N/m (J/m2) Current Smart Materials, 2017, Vol. 2, No. 1 Nanoindentation and Scratch test on Thin Film Energy Materials CONCLUSION The nanoindentation performed on coatings gave an insight into the coating failure mechanism.

Mechanicals properties were measured with monotonic nanoindentation test developed by CSM instruments Switzerland (Anton Paar) using a diamond Berkovich tip. The evaluation of the interface behavior of the PVD film was performed using scratch test. Cyclic nanoindentation test were realized in order to investigate the superficial fatigue resistance. Using samples fabricated by reactive sputtering, nanoindentation hardness depth profiles were correlated with practical scratch resistance using three different scratch and abrasion test methods .

The "Nanoindentation and Scratch Test Instruments Market" reached a valuation of USD xx.x Billion in 2023, with projections to achieve USD xx.x Billion by 2031, demonstrating a compound annual . Considerable research has demonstrated that the nanoindentation test is an effective method to acquire the mechanical properties at the nano- and micro-scales . Crack propagation and the material removal mechanism of glass–ceramics by the scratch test. J. Mech. Behav. Biomed. Mater., 64 (2016), pp. 75-85.Keywords: scratch test, nanoindentation, scratches hardness, copper 1 INTRODUCTION Nanoindentation has been established as an important tool for measuring mechanical properties of both bulk solids and thin films on the submicron scale [1-3]. An extensive study of nanoindentation on copper films has .Compact surface materials tester with a patented integrated 3D profilometer. The SMT-5000 is an all-in-one modular platform that measures hardness (instrumented indentation), scratch adhesion & cohesion, scratch hardness, film thickness, and multi-pass wear at nano and micro scale. Each indentation and scratch test is precise, ISO, and ASTM compliant.

Japan Nanoindentation and Scratch Test Instruments Market By Type Nanoindentation Instruments Scratch Test Instruments Tribometers Microhardness Testers Surface . All engineering surfaces follow real elastic–plastic deformation behavior with work hardening [1, 3, 5, 8, 9].The deformation pattern of a real elastic–plastic sample during and after indentation is shown schematically in Fig. 3a [].The contact depth (h c) is defined as the depth of indenter in contact with the sample under load.The depth measured during the indentation (h) . After the scratch test, the results need to be carefully examined. Using a high-resolution or scanning electron microscope, the scratch is observed to determine the force at which the first cracks formed or when the coating chipped off. . Alemnis offers state-of-the-art nanoindentation technology for academia and industry. Alemnis was founded .

nanoindentation equation

webEvoPlay — провідний розробник комплексних рішень і продуктів для ігрової онлайн-індустрії. На основі багаторічного досвіду роботи в сегменті онлайн-розваг ми спроектували та розробили .

scratch test nanoindentation|nano indentation depth testing